Overview

304 Stainless simbi imhando yepasi rose Stainless simbi, ngura kuramba yakasimba kudarika 200 series ye Stainless steel material, high temperature resistance is also better, inogona kusvika 1000-1200 degrees.304 Stainless steel ine yakanakisa corrosion resistance uye corrosion resistance pakati pezviyo.Kune oxidizing % acid inovira, 6 acid inovira muyedzo, nitric acid inovira mukuedza ≤ tembiricha ye oxidizing ≤ 304 Stainless simbi ine yakasimba corrosion resistance.Iyo zvakare ine yakanaka corrosion resistance kune alkaline solution uye yakawanda organic and inorganic acids.

Tsanangudzo

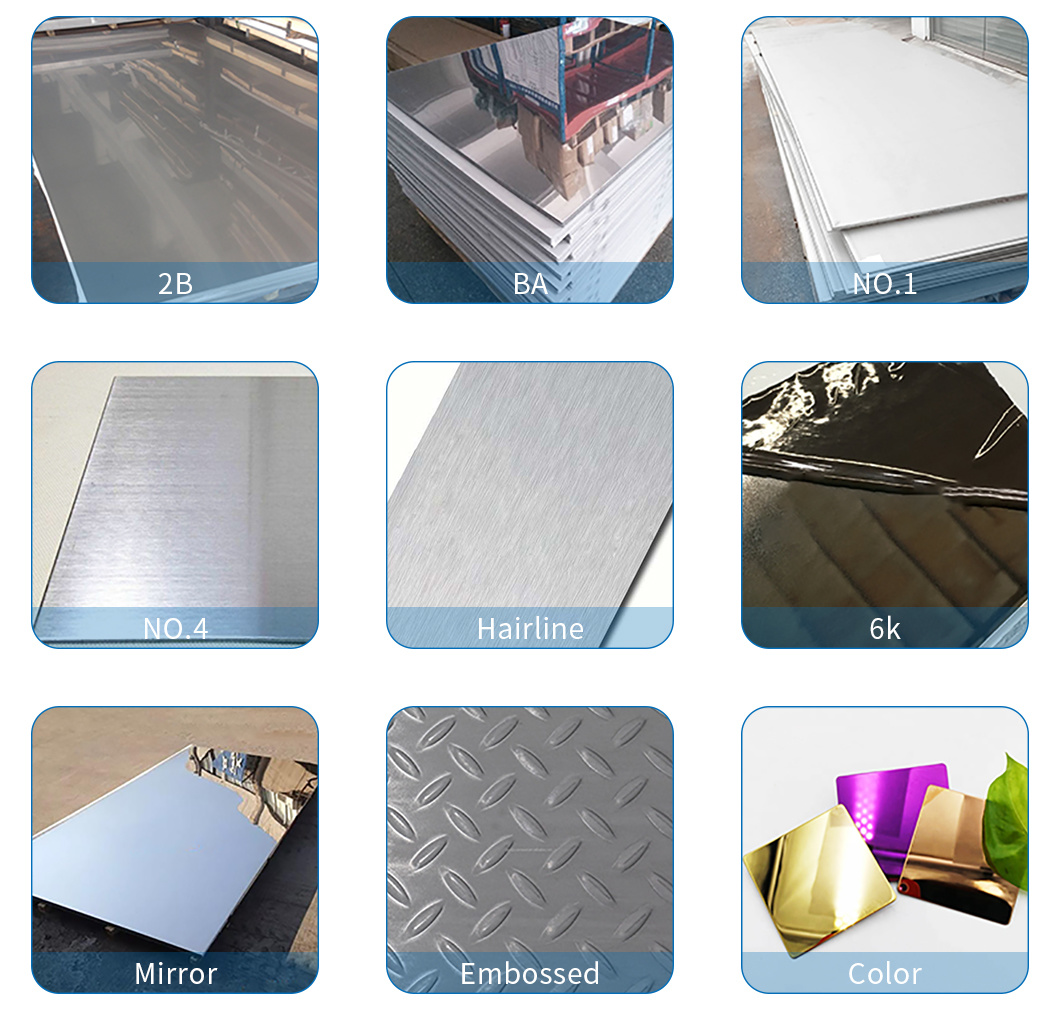

| Surface Finish | Tsanangudzo |

| 2B | Mhedzisiro yakajeka, mushure mekutonhora kukunguruka, nekurapa kwekupisa, inogona kushandiswa zvakananga, kana senhanho yekutanga yekupuruzira. |

| 2D | Nzvimbo yakasvibira, inokonzeresa nekukunguruka kunotonhora kunotevera nekurembera nekudzika. Inogona kuwana yekupedzisira mwenje roll inopfuura nemumapumburu asina kukwenenzverwa. |

| BA | Bright Annealed finish iyo inowanikwa nekuvharisa zvinhu pasi pemhepo kuitira kuti chikero chisaburitswe pamusoro. |

| Nha.1 | Kupedzwa kwakashata, kwakagomara, kunobva pakupisa kukunguruka kusvika kuhukobvu hwakatarwa. Inoteverwa neannealing uye descaling. |

| Nha.3 | Kupera uku kunokwenenzverwa neNo.100 kusvika kuNo.120 abrasive inotsanangurwa muJIS R6001. |

| Nha.4 | Kupera uku kunokwenenzverwa neNo.150 kusvika kuNo.180 abrasive inotsanangurwa muJIS R6001. |

| Hairline | Mhedziso yakanaka, yakachengetedzwa nePVC firimu isati yashandiswa, inoshandiswa mukitchenware, |

| 8K Mirror | Iyo "8" mu8K inoreva chikamu chezvikamu zvealloy (304 simbi isina tsvina inonyanya kureva zviri mukati mezvinhu), "K" inoreva giredhi rekuratidzira mushure mekupenya. 8K girazi repamusoro ndiyo girazi repamusoro giredhi rinoratidzwa nechrome nickel alloy simbi. |

| Embossed | Embossed Stainless steel sheets zvinhu zvakasiyana-siyana zvinoshandiswa kugadzira kushongedza kwepamusoro pesimbi. Iwo isarudzo yakanakisa yemapurojekiti ekuvaka, splashbacks, signage, nezvimwe. Iwo akareruka zvakanyanya, uye anogona kuumbwa kuti asangane nezvinotsanangurwa zveakasiyana akasiyana maapplication. |

| Color | Coloured Steel is titanium coated Stainless simbi. Iwo mavara anowanikwa nekushandisa PVD derivate process. Mafomu ari pamusoro pepepa rega rega anopa marudzi akasiyana-siyana ekuputira, akadai seoxides, nitrides uye carbides. |

Izvo Zvikuru Zvishandiso ndizvo

1. Used yekugadzirisa marudzi ese ezvikamu zvakajairika uye zvekudhinda kufa;

2.Used seyakanyanya kurongeka zvikamu zvesimbi;

3. Inoshandiswa zvakanyanya mukupisa kurapa kwekushushikana kwekunetseka annealing isati yakotama.

4. Inogona kushandiswa sechinhu chekuvaka chekuvaka kwehurumende.

7. Inogona kushandiswa muindasitiri yemotokari.

8. Inogona kushandiswa kuindasitiri yemidziyo yemumba. The nuclear energy sector. Nzvimbo uye ndege. Munda wemagetsi nemagetsi. Medical michina indasitiri. Indasitiri yekuvaka ngarava.

Kemikari Inoumbwa yeKakawanda Inoshandiswa Stainless Steel

| Giredhi | C | Si | Mn | P | S | Ni | Cr | Mo | Vamwe |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | ― | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | ― | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Mirror Ruvara Stainless Simbi Sheet muS...

-

316L 2B Checkered Stainless Steel Sheet

-

304 Colored Stainless Steel Sheet Etching Plates

-

430 Perforated Stainless Steel Sheet

-

SUS304 Embossed Stainless Simbi Sheet

-

201 J1 J3 J5 Stainless Steel Sheet

-

Perforated Stainless Steel Sheets

-

PVD 316 Colored Stainless Steel Sheet

-

SUS304 BA Stainless Steel Sheets Best Rate

-

SUS316 BA 2B Stainless Steel Sheets Supplier