Brass

Kushandiswa kwendarira nemhangura kwakatangira mazana emakore, uye nhasi kuri kushandiswa mune mamwe emazuva ano matekinoroji uye maapplication achiri kushandiswa mamwe echinyakare maapplication akadai sezviridzwa zvemumhanzi, ziso rendarira, zvinyorwa zvekushongedza uye tepi nemasuo hardware.

Brass Yakagadzirwa Nechii?

Brass ialloy yakagadzirwa kubva musanganiswa wemhangura uye zinc kugadzira zvinhu zvine huwandu hwakasiyana hwekushandisa huinjiniya. Brass kuumbwa kunopa simbi kunyungudika kwakakodzera kune akawanda maapplication, kusanganisira akakodzera kujoinha uchishandisa brazing maitiro. Kunyunguduka kwendarira kwakadzikira pane mhangura kunosvika 920 ~ 970 madhigirii celsius zvichienderana nehuwandu hwekuwedzera kweZn. Brass inonyungudika yakadzikira pane iya yemhangura nekuda kweiyo Zn yakawedzerwa. Brass alloys inogona kusiana mukuumbwa kweZn kubva padiki se5% (inonyanya kunzi Gilding Metals) kusvika pamusoro pe40% sekushandiswa mumachining brasses. Izwi risingawanzo shandiswa ibhuronzi, uko kumwe kuwedzeredzwa kwerata kunoshandiswa.

Brass inoshandiswa nei?

Brass kuumbwa uye kuwedzerwa kwezingi kune mhangura kunosimudza simba uye kunopa huwandu hwemaitiro, izvo zvinoita kuti mabhurashi ave akasiyana-siyana emhando yezvinhu. Iwo anoshandiswa kune simba rawo, corrosion resistance, chitarisiko uye ruvara, uye nyore kushanda nekubatana. Chikamu chimwe chete che alpha brasses, ine inosvika 37% Zn, inonyatso ductile uye iri nyore kutonhora basa, weld uye braze. Iwo maviri echikamu alpha-beta brasses anowanzo kupisa anoshandiswa.

Pane zvinopfuura imwe brass yakagadzirwa here?

Kune akawanda mabhurasi ane akasiyana maumbirwo uye maitiro akarongedzerwa kune chaiwo maapplication nehuwandu hwekuwedzera zinc. Iwo akaderera mazinga eZn yekuwedzera anowanzo kunzi Guilding Metal kana Red Brass. Nepo iwo epamusoro mazinga eZn ari alloys akadai seCartridge Brass, Yemahara Machining Brass, Naval Brass. Aya mabhurashi akazotevera anewo kuwedzera kwezvimwe zvinhu. Kuwedzerwa kwemutobvu kundarira kwave kuchishandiswa kwemakore akawanda kubatsira machinability yezvinhu nekukwevera chip break point. Sezvo njodzi uye njodzi yemutobvu yakaonekwa ichangobva kutsiviwa nezvinhu zvakaita sesilicon uye bismuth kuti iwane yakafanana machining hunhu. Aya ave kuzivikanwa seakaderera lead kana lead yemahara brasses.

Zvimwe zvinhu zvinogona kuwedzerwa here?

Hongu, zvidiki zvidiki zvezvimwe zvinosanganiswa zvinhu zvinogonawo kuwedzerwa kumhangura nendarira. Mienzaniso yeCommons inotungamira yekugona-muchina sezvataurwa pamusoro, asiwo arsenic yekudzivirira ngura kune dezincification, tin yesimba uye ngura.

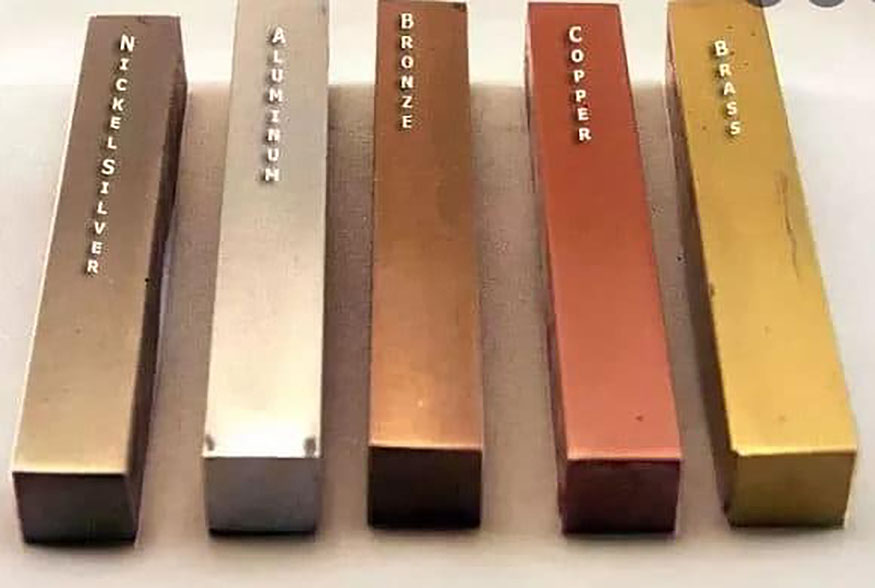

Brass Ruvara

Sezvo iyo zinc yemukati inowedzerwa, ruvara runoshanduka. Iyo yakaderera Zn alloys inogona kuwanzoita semhangura muruvara, nepo yakakwira zinc alloys inoratidzika yegoridhe kana yero.

Kuumbwa Kwemakemikari

AS2738.2 -1984 Zvimwe zvinotsanangurwa zvinenge zvakaenzana

| UNS Nha | AS Nha | Common Name | BSI Nha | ISO Nha | JIS Nha | Mhangura % | Zinc % | Tungamira % | Vamwe % |

| C21000 | 210 | 95/5 Gilding Metal | - | CuZn5 | C2100 | 94.0-96.0 | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding Metal | CZ101 | CuZn10 | C2200 | 89.0-91.0 | ~ 10 | <0.05 | |

| C23000 | 230 | 85/15 Gilding Metal | CZ102 | CuZn15 | C2300 | 84.0-86.0 | ~ 15 | <0.05 | |

| C24000 | 240 | 80/20 Gilding Metal | CZ103 | CuZn20 | C2400 | 78.5-81.5 | ~ 20 | <0.05 | |

| C26130 | 259 | 70/30 Arsenical Brass | CZ126 | CuZn30As | ~C4430 | 69.0-71.0 | ~ 30 | <0.07 | Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 Brass | CZ106 | CuZn30 | C2600 | 68.5-71.5 | ~ 30 | <0.05 | |

| C26800 | 268 | Yellow Brass (65/35) | CZ107 | CuZn33 | C2680 | 64.0-68.5 | ~ 33 | <0.15 | |

| C27000 | 270 | 65/35 Wire Brass | CZ107 | CuZn35 | - | 63.0-68.5 | ~ 35 | <0.10 | |

| C27200 | 272 | 63/37 Common Brass | CZ108 | CuZn37 | C2720 | 62.0-65.0 | ~ 37 | <0.07 | |

| C35600 | 356 | Engraving Brass, 2% Lead | - | CuZn39Pb2 | C3560 | 59.0-64.5 | ~ 39 | 2.0-3.0 | |

| C37000 | 370 | Engraving Brass, 1% Lead | - | CuZn39Pb1 | ~C3710 | 59.0-62.0 | ~ 39 | 0.9-1.4 | |

| C38000 | 380 | Chikamu Brass | CZ121 | CuZn43Pb3 | - | 55.0-60.0 | ~ 43 | 1.5-3.0 | Aluminium 0.10-0.6 |

| C38500 | 385 | Yemahara Yekucheka Brass | CZ121 | CuZn39Pb3 | - | 56.0-60.0 | ~ 39 | 2.5-4.5 |

Brasses inowanzoshandiswa pakuonekwa kwavo

| UNS Nha | Common Name | Color |

| C11000 | ETP Mhangura | Soft Pink |

| C21000 | 95/5 Gilding Metal | Red Brown |

| C22000 | 90/10 Gilding Metal | Ndarama yeBronze |

| C23000 | 85/15 Gilding Metal | Tan Gold |

| C26000 | 70/30 Brass | Green Gold |

Gilding Metal

C22000, 90/10 Gilding simbi, inosanganisa yakapfuma yegoridhe ruvara ine yakanakisa musanganiswa wesimba, ductility uye corrosion kuramba kwebani Cu-Zn alloys. Inoita mamiriro ekunze kusvika kune yakapfuma ruvara rwebronze. Iyo ine yakanakisa yakadzika yekudhirowa kugona, uye kuramba kune gomba corrosion mumamiriro ekunze akaoma uye mvura nharaunda. Inoshandiswa mukugadzira fascias, jewellery, ornamental trim, mibato yemagonhi, escutcheons, marine hardware.

Yellow brasses

C26000, 70/30 Brass uye C26130, Arsenical brass, ine ductility yakanakisa uye simba, uye ndiyo inonyanya kushandiswa ndarira. Arsenical brass ine kuwedzera kudiki kwe arsenic, iyo inovandudza zvakanyanya kusagadzikana kwemarara mumvura, asi neimwe nzira zvinobudirira zvakafanana. Aya alloys ane ruvara rwakajeka rweyero rinowanzobatanidzwa nendarira. Ivo vane optimum musanganiswa wesimba uye ductility muCu-Zn alloys, akasanganiswa neakanaka corrosion kuramba. C26000 inoshandiswa pakuvaka, kudhirowa uye kuruka midziyo uye maumbirwo, materminal emagetsi uye zvinobatanidza, zvibato zvemagonhi, uye plumber hardware. C26130 inoshandiswa kune chubhu uye zvigadziriso zvinosangana nemvura, kusanganisira mvura inonwiwa.

C26800, Yellow brass,ndiyo chikamu chimwe chete alpha brass ine yakaderera zvirimo mumhangura. Inoshandiswa uko yakadzika yekudhirowa zvimiro uye yakaderera mutengo inopa mukana. Kana welded zvimedu zve beta chikamu zvinogona kuumba, kuderedza ductility uye corrosion kuramba.

Brasses nezvimwe zvinhu

C35600 neC37000, Engraving brass, i60/40 alpha-beta brasses ine mazinga akasiyana emutobvu akawedzerwa kupa mahara machining maitiro. Iwo anoshandiswa zvakanyanya kune akavezwa mahwendefa uye plaques, vavaki Hardware, magiya. Izvo hazvifanirwe kushandiswa kune acid-etched basa, iyo iyo imwe-phase alpha brasses inofanira kushandiswa.

C38000, Chikamu chendarira, iri nyore extrudable leaded alpha/beta brass ine diki aruminiyamu yekuwedzera, iyo inopa yakajeka goridhe ruvara. Iyo inotungamira inopa mahara ekucheka maitiro. C38000 inowanikwa sematanda eextruded, chiteshi, mafurati nemakona, ayo anowanzo shandiswa muvaki Hardware.

C38500, kucheka ndarira, imhando yakagadziridzwa zvakanyanya ye60/40 ndarira, ine yakanakisa yemahara-yekucheka maitiro. Inoshandiswa mukugadzirwa kwakawanda kwezvikamu zvendarira uko kunodiwa kuburitsa kwakanyanya uye hupenyu hurefu hwematurusi, uye uko pasina imwe kutonhora kuumba mushure mekugadzira kunodiwa.

Brass Zvigadzirwa list

● Chigadzirwa Form

● Zvigadzirwa zvakafuratira

● Matanda akagadzirwa, mbariro & zvikamu

● Forging stock & forgings

● Machubhu asina musono ezvinopisa kupisa

● Machubhu asina musono ekugadzirisa mhepo & firiji

● Machubhu asina musono ezvinangwa zveinjiniya

● Waya yezvinangwa zveinjiniya

● Waya yezvinangwa zvemagetsi

Jindalai Steel Group inopa zvakasiyana-siyana zvigadzirwa zvendarira muhukuru uye huwandu hwekusangana nezvinodiwa zvechero chirongwa. Isu tinobvumawo maitiro echinyakare, saizi, maumbirwo, uye mavara. Tumira kubvunza kwako uye isu tichafara kukubvunza iwe nehunyanzvi.

HOTLINE:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE:www.jindalaisteel.com

Nguva yekutumira: Zvita-19-2022