Mhedziso ye430 Stainless Steel

SS430 isimbi isina tsvina ine ferritic ine corrosion resistance inoswedera kune iyo ye304/304L simbi isina tsvina. Iri giredhi harishande nekukasira uye rinogona kuumbwa uchishandisa ese ari maviri akapfava akatambanudzwa kuumba, kukotama, kana kudhirowa mabasa. Iri giredhi rinoshandiswa mune akasiyana emukati uye ekunze cosmetic application uko kushorwa kwecorrosion kwakakosha kupfuura simba.SS430 ine urombo husina kusimba kana ichienzaniswa neakawanda simbi isina tsvina nekuda kweiyo yakakwira kabhoni yemukati uye kushomeka kwezvinhu zvinodzikamisa zvegiredhi iri, izvo zvinoda post weld kupisa kurapwa kudzoreredza kuramba kwecorrosion uye ductility. Yakagadzikana mamakisi akadaiSS439 uye 441 inofanirwa kutariswa kune welded ferritic Stainless steel application.

Tsanangudzo ye430 Stainless Steel

| Product Name | 430 Stainless Simbi Coil | |

| Type | Kutonhora/Kupisa kwakakunguruka | |

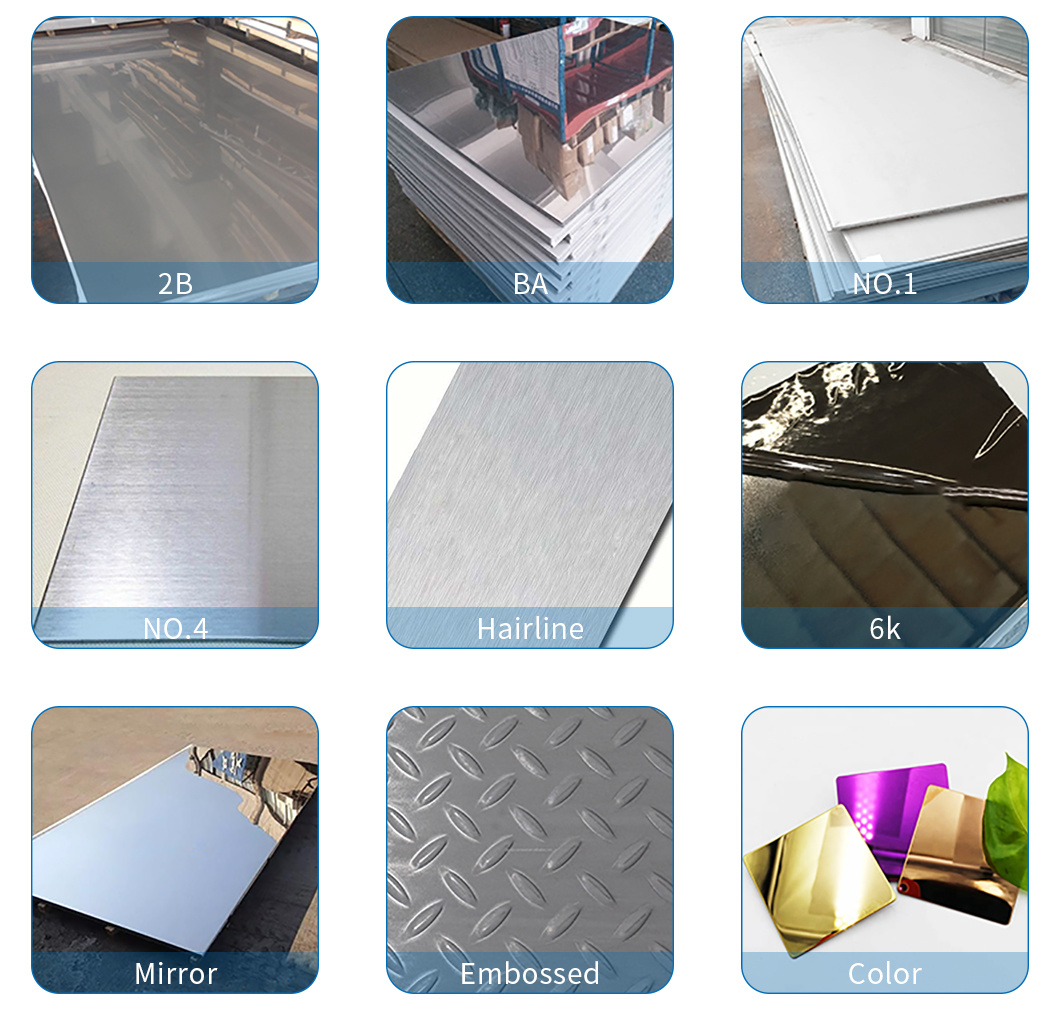

| Surface | 2B 2D BA(Bright Annealed) No1 No3 No4 No5 No8 8K HL(Hair Line) | |

| Giredhi | 201 / 202 / 301 / 303/ 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 318/ 321 / 403 / 410 / 430/ 904L / 2305 / 250 / 250 / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 nezvimwe | |

| Ukobvu | Kutonhora kwakakungurutswa 0.1mm - 6mm Kupisa kwakatenderedzwa 2.5mm-200mm | |

| Upamhi | 10mm - 2000mm | |

| Application | Kuvaka, Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. | |

| Processing Service | Machining : Kutendeuka / Kugaya / Kuronga / Kuchera / Kubhowa / Kukuya / Kucheka Gear / CNC Machining | |

| Deformation kugadzirisa: Kupeta / Kucheka / Kutenderedza / Kutsikisa Welded / Forged | ||

| MOQ | 1ton. Isu tinogonawo kubvuma kurongeka kwemuenzaniso. | |

| Delivery nguva | Mukati me10-15 mazuva ekushanda mushure mekugamuchira dhipoziti kana L / C | |

| Packing | Bepa risina mvura, uye simbi yesimbi yakarongedzwa.Standard Export Seaworthy Package. Inokodzera mhando dzese dzekutakura, kana sezvinodiwa | |

Kemikari Inoumba Mechanical Properties ye430

| ASTM A240/A240M (UNS Dhizaini) | S43000 |

| Kuumbwa Kwemakemikari | |

| Chromium | 16-18% |

| Nickel (max.) | 0.750% |

| Carbon (max.) | 0.120% |

| Manganese (max.) | 1.000% |

| Silicon (max.) | 1.000% |

| Sarufa (max.) | 0.030% |

| Phosphorus (max.) | 0.040% |

| Mechanical Properties (yakabatanidzwa) | |

| Tensile (min. psi) | 65,000 |

| Goho (min. psi) | 30,000 |

| Elongation (mu2″, min %) | 20 |

| Kuoma (max Rb) | 89 |

-

201 304 Ruvara Yakavharwa Inoshongedza Stainless Simbi...

-

201 Cold Yakakungurutswa Coil 202 Stainless Steel Coil

-

201 J1 J2 J3 Stainless Steel Coil/Strip Stockist

-

316 316Ti Stainless Steel Coil

-

430 Stainless Simbi Coil/Strip

-

8K Mirror Stainless Steel Coil

-

904 904L Stainless Steel Coil

-

Colored Stainless Steel Coil

-

Duplex 2205 2507 Stainless Steel Coil

-

Duplex Stainless Simbi Coil

-

Rose Goridhe 316 Stainless Steel Coil

-

SS202 Stainless Simbi Coil / Strip muStock

-

SUS316L Stainless Steel Coil/Strip